School of Physics and Astronomy, University of Nottingham

Equipment and Capabilities

A few of the highlights of our experimental capabilities are described below. Our approach to science often results in us building our own equipment as well as writing the software to control it and collect the data.

Sample Preparation

Blade Coater

Solution processing of thin (microns) films using a custom built blade coater. The carriage is capapable of achieving coating speeds between 10 and 200 mm per second. The blade height is adjustable to allow for levelling and control of film thickness.

Spin Coater

Solution processing of ultrathin (nanometre) films using a custom built spin coater. A vacuum chuck is used to hold the sample in place. Spin speeds are typically in the range 0-5,000rpm, although speeds up to 10,000rpm are achievable.

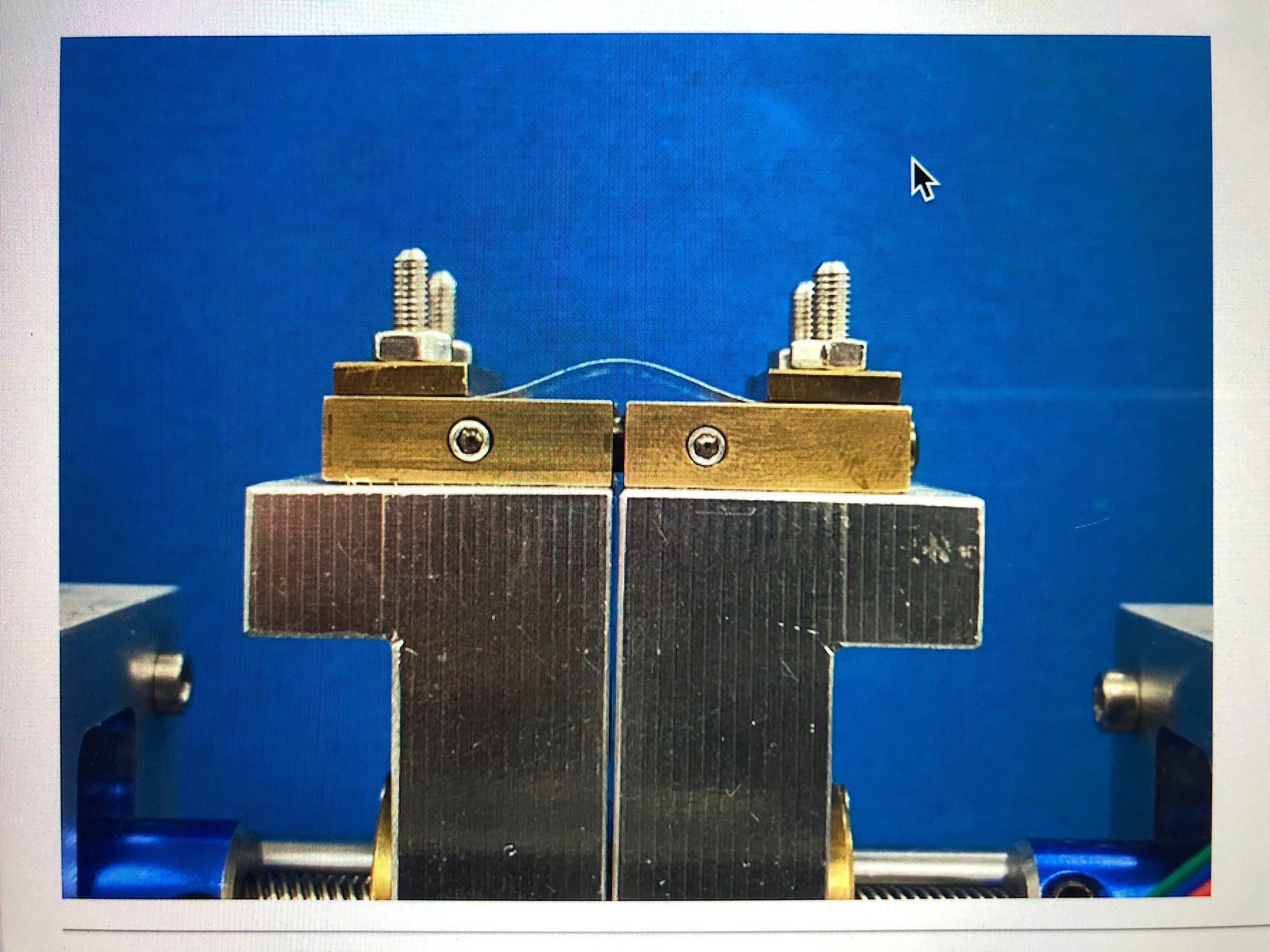

Sample Bending/Stretching Stage

This simple stage allows us to apply controlled deformations (strecthing or bending) to samples. Stepper motors are used to control the extent of deformation. The sample holder can be locked in place after a deformation has been applied and removed from the stage for imaging or for use on other instruments.

Sample Characterisation and Measurement

Ellipsometry

Ellipsometry uses changes in the polarisation state of light to measure the thickness and refractive index of utrathin films. Our custom built variable angle ellipsometer is a single wavelength (633 nm) self-nulling instrument that is capabale of measuring thickness with a precision of 1 nanometre and differences in refractive index of 0.001.

Optical Microscopy

The Olympus BX51 optical microscope is something of a work-horse in the laboratory. It is equipped with fluorescence capabilities, differential interference contrast, bright-field, dark-field and has a range of different objectives. The trinocular head allows for simultaneous viewing by the user and with a high resolution colour USB camera. It can also be operated in reflection or transmission modes and has two dedicated Linkam THMS600 temperature control stages. Software written in Python allows us to acquire images at a range of different frame rates and to perform our own, custom data/image processing.

Video Imaging

Our lab has a suite of USB cameras with a range of different frame rates and resolutions, as well as a set of fixed and variable focal length lenses. These are used to perform video imaging of thin film samples and droplets. The setup shown in the image was used to study the growth of telephone cord blisters in thin elastomer films.

UHV Rotation Stage

Our ultra high vacuum compatible rotation stage was developed to allow us to perform Time of Flight Secondary Ion Mass Spectromeytry (ToF SIMS) measurements on cylindrical samples. It contains a low-profile stepper motor stage that was originally built to enable us to image the surfaces of bullet casings. It can also be used to image other samples that have a cylindrical geometry.

Couette Flow cell

Our transparent Couette cell allows us to shear multi-layers of fluids and use video imaging to study the motion of the interfaces between the layers. We are interested in studying interfacial instabilities in simple fluid systems and systems that include surfactant and/or viscoelastic materials.

Contact Imaging Platform

This platform allows us to image the contact regions beneath shoes and feet while a subject performs natural movements (e.g. standing, jumping, jogging). A camera placed below the platform acquires images with millisecond time and millimetre spatial resolution. These images are converted into pressure maps that can be synchronised and correlated with images (of e.g. joint angles) collected from above the platform. Integral load sensors beneath the platform allows us to calibrate the data obtained in the images.